مميزة

- الحصول على الرابط

- X

- بريد إلكتروني

- التطبيقات الأخرى

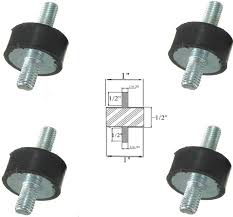

Maximizing Stability: The Benefits of Floor Vibration Isolators

Floor vibration isolators are an essential component in maximizing vibration isolators stability and minimizing the impact of vibrations in various settings. Whether in a laboratory, manufacturing facility, or commercial space, the use of floor vibration isolators can greatly benefit the overall stability and functionality of the environment. By effectively reducing the transmission of vibrations through the floor, these isolators contribute to a safer and more controlled workspace. In this article, we will explore the key benefits of floor vibration isolators and how they can be utilized to maximize stability in different applications.

Maximizing stability with floor vibration isolators can significantly benefit industrial and commercial operations. These isolators are designed to reduce the impact of floor vibrations, which can result from heavy machinery, equipment, or foot traffic, ultimately leading to improved stability and safety in the work environment. By minimizing vibrations, these isolators help to protect sensitive instruments, machinery, and electronic equipment from potential damage, ensuring their longevity and accurate performance. Additionally, workers are likely to experience decreased fatigue and improved comfort when working in a stable and vibration-free environment. The use of floor vibration isolators also enhances productivity by reducing downtime for repairs and maintenance caused by excessive vibrations. This results in cost savings and improved operational efficiency. Overall, the benefits of floor vibration isolators in maximizing stability extend to equipment longevity, worker comfort, and operational productivity Vibration Isolation Systems in various industrial and commercial settings.

Maximizing stability with floor vibration isolators involves reducing the impact of vibrations caused by heavy machinery or foot traffic in industrial and commercial settings. These isolators help protect sensitive equipment from potential damage and improve worker comfort by minimizing fatigue. They also contribute to improved productivity and cost savings by reducing downtime for repairs and types of vibration isolators maintenance. Overall, floor vibration isolators play a crucial role in enhancing stability, safety, and operational efficiency in various work environments.

The Importance of Floor Vibration Isolator in Noise Reduction

A floor vibration isolator plays a crucial role in reducing noise in a building by minimizing vibrations and impact sounds transmitted through the floor. This is especially important in environments where noise reduction is a priority, such as recording studios, theaters, and commercial office spaces. By isolating the floor from the structure of the building, the isolator helps to prevent vibrations and impact sounds from traveling through the floor and creating unwanted noise. This can improve the overall acoustics of a space and create a more pleasant and productive environment for occupants. In addition to noise reduction, floor vibration isolators can also help to protect sensitive equipment and machinery from damage caused by excessive vibrations. Overall, the importance of floor vibration isolators in noise reduction cannot be understated in creating a comfortable and functional indoor environment.

Choosing the Right Floor Vibration Isolator for Your Space

When choosing the right floor vibration isolator for your space, it is important to consider the weight and size of the equipment you are trying to isolate, the frequency and amplitude of the vibrations, as well as the specific requirements of the space. Selecting the appropriate isolator will help to minimize vibrations and provide a more stable environment for sensitive equipment and machinery. It is also important to consider the installation and maintenance requirements of the isolator, as well as any additional features such as leveling and height adjustment capabilities. By carefully evaluating these factors, you can choose the right floor vibration isolator to meet the needs of your space and equipment.

How Floor Vibration Isolators enhance Equipment Performance

Floor vibration isolators enhance equipment performance by reducing the impact of external vibrations on the machinery. These isolators act as a buffer between the equipment and the floor, absorbing the energy from vibrations and preventing it from affecting the performance or accuracy of the machinery. This is particularly beneficial for precision equipment, such as laboratory instruments or manufacturing machinery, where even small vibrations can lead to decreased productivity or compromised results. By minimizing the impact of floor vibrations, isolators help to improve the overall efficiency and effectiveness of the equipment, ultimately leading to better performance and results.

Factors to Consider When Installing Floor Vibration Isolators

- Determine the load capacity of the isolators to ensure they can support the weight of the equipment and structure - Consider the natural frequency of the isolators to ensure they are compatible with the frequency of vibrations present - Ensure proper placement and spacing of the isolators to effectively reduce vibration transmission - Evaluate environmental conditions such as temperature, moisture, and chemical exposure to select isolators with the appropriate material and protective coating - Assess the potential impact of the isolators on the overall height and stability of the flooring system - Consider the installation and maintenance requirements of the isolators to ensure long-term effectiveness in reducing vibrations

Understanding the Science Behind Floor Vibration Isolators

Floor vibration isolators are essential for minimizing the transmission of unwanted vibrations from equipment and machinery to the surrounding environment. These isolators are designed to effectively absorb and dissipate vibrations, preventing them from traveling through the floor and causing disturbances or damage. Understanding the science behind floor vibration isolators involves a grasp of principles such as resonance, damping, and natural frequency. Resonance occurs when the frequency of a vibrating system matches the natural frequency of the isolator, resulting in amplified vibrations. Damping is the process of dissipating energy from vibrations, while natural frequency refers to the frequency at which a system oscillates in the absence of external forces. The effectiveness of floor vibration isolators depends on various factors, including the material properties, design, and installation. Proper selection and placement of isolators are crucial for achieving the desired level of vibration isolation. Additionally, considerations such as load capacity, environmental conditions, and maintenance requirements play a significant role in the performance and longevity of floor vibration isolators. By understanding the science behind floor vibration isolators, engineers and facility managers can make informed decisions regarding the selection and implementation of isolators to ensure minimal vibration transmission and optimal operational conditions.

The Benefits of Floor Vibration Isolators in Industrial Settings

Floor vibration isolators are crucial in industrial settings for several reasons. First and foremost, they help to minimize the transmission of vibrations from heavy machinery to the building structure, preventing potential damage to the facility. This is particularly important in industries such as manufacturing, where large and powerful equipment is often in use. Additionally, floor vibration isolators can improve the working environment for employees by reducing noise and vibrations, which can lead to increased comfort and productivity. By minimizing the impact of machinery vibrations, these isolators also help to extend the lifespan of equipment and reduce maintenance costs. In some cases, floor vibration isolators are necessary for compliance with workplace safety standards and regulations. By providing a stable and vibration-free work environment, these isolators contribute to a safer workplace for employees. Overall, the benefits of floor vibration isolators in industrial settings are clear. They help to protect the facility, improve the working environment, reduce maintenance costs, and ensure compliance with safety regulations. As a result, investing in high-quality vibration isolators is a wise decision for any industrial facility.

Maximizing Comfort with Floor Vibration Isolators in Buildings

Floor vibration isolators are used in buildings to maximize comfort by reducing the transmission of vibrations from various sources, such as machinery, foot traffic, or structural movements. These isolators are typically made from materials like rubber or neoprene and are designed to absorb and dampen the vibrations before they can transfer through the floor. This helps to create a quieter and more stable environment, particularly in buildings with sensitive equipment or where occupant comfort is a priority. By effectively isolating floor vibrations, these systems can greatly improve the overall comfort and usability of a building.

Improving Safety and Stability with Floor Vibration Isolators

Floor vibration isolators are devices designed to reduce the transmission of vibration and noise from machinery and equipment into the surrounding structure. They are commonly used in industrial and commercial settings to improve safety and stability by minimizing the impact of vibrations on the floor and nearby equipment or structures. These isolators typically consist of a resilient material, such as rubber or neoprene, housed within a metal casing. When placed under heavy machinery or equipment, they absorb and dampen the vibrations generated during operation, preventing them from being transmitted to the floor and adjacent structures. By using floor vibration isolators, businesses can minimize the risk of structural damage, improve worker safety, and reduce the negative effects of vibration and noise on nearby equipment. This can result in a more efficient and comfortable work environment while extending the lifespan of machinery and reducing maintenance costs. Overall, floor vibration isolators play a crucial role in ensuring safety and stability in industrial and commercial settings, making them an essential component for many businesses and facilities.

In conclusion, floor vibration isolators are a crucial tool for maximizing stability in various applications. By effectively reducing vibrations and disturbances, these isolators offer numerous benefits such as improved equipment performance, reduced structural wear, and enhanced safety for both people and sensitive machinery. Investing in high-quality floor vibration isolators can ultimately lead to a more efficient and productive environment. Whether it's in a manufacturing facility, laboratory, or residential setting, the use of floor vibration isolators can make a significant difference in overall stability and performance.

vibration isolation types

See also

https://www.rticontrols.com/vibration-isolation https://www.rubbergroup.com/products/vibration-isolators- الحصول على الرابط

- X

- بريد إلكتروني

- التطبيقات الأخرى

المشاركات الشائعة

المنشأة الفردية في القانون المصري: الإجراءات القانونية والتشريعية المتعلقة

- الحصول على الرابط

- X

- بريد إلكتروني

- التطبيقات الأخرى